Custom Hydraulic Cylinder Applications

Superior quality, durability, and efficiency come together in RAYDAFON HYDRAULIC cylinders, which tailored to all your specific needs.

|

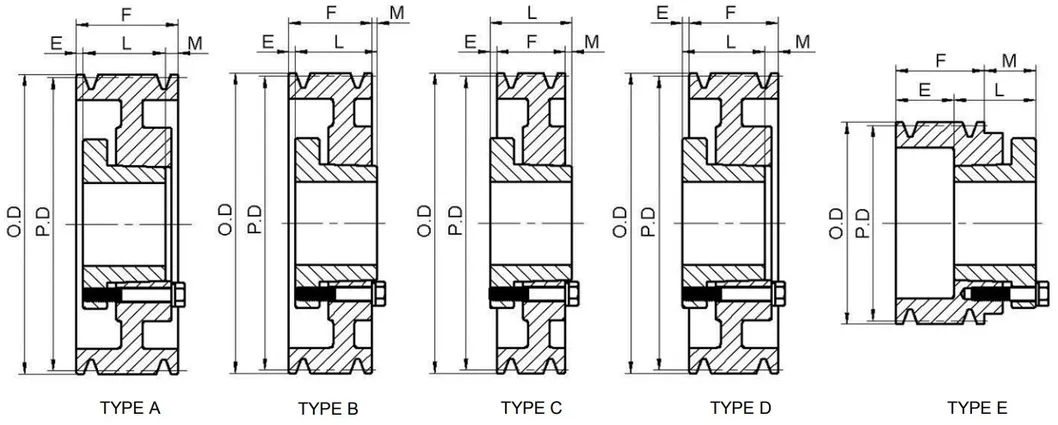

Size

|

Bushing Type

|

Type

|

Pitch Diameter

|

Outside Diameter

|

(E)

|

(F)

|

(L)

|

(M)

|

Weight (LBS)

|

|

65V440SD

|

SD

|

E

|

4.30"

|

4.40"

|

3 25/32"

|

4 7/16"

|

1 13/16"

|

21/32"

|

10.1

|

|

65V465SD

|

SD

|

E

|

4.55"

|

4.65"

|

3 25/32"

|

4 7/16"

|

1 13/16"

|

21/32"

|

10.4

|

|

65V490SD

|

SD

|

A

|

4.80"

|

4.90"

|

21/32"

|

4 7/16"

|

1 13/16"

|

1 31/32"

|

11.2

|

|

65V520SD

|

SD

|

A

|

5.10"

|

5.20"

|

21/32"

|

4 7/16"

|

1 13/16"

|

1 31/32"

|

12.1

|

|

65V550SD

|

SD

|

A

|

5.40"

|

5.50"

|

21/32"

|

4 7/16"

|

1 13/16"

|

1 31/32"

|

13.3

|

|

65V590SK

|

SK

|

A

|

5.80"

|

5.90"

|

17/32"

|

4 7/16"

|

1 15/16"

|

1 31/32"

|

14.6

|

|

65V630SK

|

SK

|

A

|

6.20"

|

6.30"

|

17/32"

|

4 7/16"

|

1 15/16"

|

1 31/32"

|

17.4

|

|

65V670SF

|

SF

|

A

|

6.60"

|

6.60"

|

25/32"

|

4 7/16"

|

2 1/16"

|

1 19/32"

|

20.0

|

|

65V710SF

|

SF

|

A

|

7.00"

|

7.10"

|

25/32"

|

4 7/16"

|

2 1/16"

|

1 19/32"

|

21.9

|

|

65V750SF

|

SF

|

A

|

7.40"

|

7.50"

|

25/32"

|

4 7/16"

|

2 1/16"

|

1 19/32"

|

23.4

|

|

65V800E

|

E

|

A

|

7.90"

|

8.00"

|

27/32"

|

4 7/16"

|

2 3/4"

|

27/32"

|

24.2

|

|

65V850E

|

E

|

A

|

8.40"

|

8.50"

|

27/32"

|

4 7/16"

|

2 3/4"

|

27/32"

|

26.7

|

|

65V900E

|

E

|

A

|

8.90"

|

9.00"

|

27/32"

|

4 7/16"

|

2 3/4"

|

27/32"

|

28.5

|

|

65V925E

|

E

|

A

|

9.15"

|

9.25"

|

27/32"

|

4 7/16"

|

2 3/4"

|

27/32"

|

30.2

|

|

65V975E

|

E

|

A

|

9.65"

|

9.75"

|

27/32"

|

4 7/16"

|

2 3/4"

|

27/32"

|

33.8

|

|

65V1030E

|

E

|

A

|

10.20"

|

10.30"

|

27/32"

|

4 7/16"

|

2 3/4"

|

27/32"

|

36.6

|

|

65V1090E

|

E

|

A

|

10.80"

|

10.90"

|

27/32"

|

4 7/16"

|

2 3/4"

|

27/32"

|

38.1

|

|

65V1130E

|

E

|

A

|

11.20"

|

11.30"

|

27/32"

|

4 7/16"

|

2 3/4"

|

27/32"

|

39.8

|

|

65V1180E

|

E

|

A

|

11.70"

|

11.80"

|

27/32"

|

4 7/16"

|

2 3/4"

|

27/32"

|

41.2

|

|

65V1250F

|

F

|

B

|

12.40"

|

12.50"

|

23/32"

|

4 7/16"

|

3 3/4"

|

1/32"

|

58.2

|

|

65V1320F

|

F

|

B

|

13.10"

|

13.20"

|

23/32"

|

4 7/16"

|

3 3/4"

|

1/32"

|

64.0

|

|

65V1400F

|

F

|

B

|

13.90"

|

14.00"

|

23/32"

|

4 7/16"

|

3 3/4"

|

1/32"

|

66.0

|

|

65V1500F

|

F

|

B

|

14.90"

|

15.00"

|

23/32"

|

4 7/16"

|

3 3/4"

|

1/32"

|

68.0

|

|

65V1600F

|

F

|

B

|

15.90"

|

16.00"

|

23/32"

|

4 7/16"

|

3 3/4"

|

1/32"

|

77.5

|

|

65V1870F

|

F

|

D

|

18.60"

|

18.70"

|

1/32"

|

4 7/16"

|

3 3/4"

|

23/32"

|

85.8

|

|

65V2120F

|

F

|

D

|

21.10"

|

21.20"

|

1/32"

|

4 7/16"

|

3 3/4"

|

23/32"

|

96.0

|

|

65V2360J

|

J

|

C

|

23.50"

|

23.60"

|

1/8"

|

4 7/16"

|

4 5/8"

|

1/16"

|

113.0

|

|

65V2800J

|

J

|

C

|

27.90"

|

28.00"

|

1/8"

|

4 7/16"

|

4 5/8"

|

1/16"

|

148.0

|

|

65V3150J

|

J

|

C

|

31.40"

|

31.50"

|

1/8"

|

4 7/16"

|

4 5/8"

|

1/16"

|

183.0

|

|

65V3750J

|

J

|

C

|

37.40"

|

37.50"

|

1/8"

|

4 7/16"

|

4 5/8"

|

1/16"

|

218.0

|

|

65V5000M

|

M

|

C

|

49.90"

|

50.00"

|

1 3/32"

|

4 7/16"

|

6 3/4"

|

1 7/32"

|

310.0

|

QD sleeve | quick disconnect sleeve

QD sleeve | quick disconnect sleeve

Address

Luotuo Industrial Area, Zhenhai District, Ningbo City, China

Tel