Custom Hydraulic Cylinder Applications

Superior quality, durability, and efficiency come together in RAYDAFON HYDRAULIC cylinders, which tailored to all your specific needs.

|

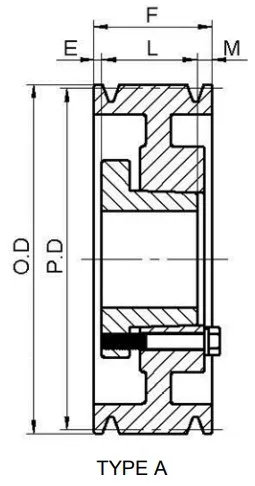

Size

|

Bushing Type

|

Type

|

Pitch Diameter

|

Outside Diameter

|

(E)

|

(F)

|

(L)

|

(M)

|

Weight (LBS)

|

|

53V475SDS

|

SDS

|

A

|

4.70"

|

4.75

|

5/32

|

2 5/16

|

1 5/16

|

27/32

|

5.1

|

|

53V500SDS

|

SDS

|

A

|

4.95"

|

5.00"

|

5/32

|

2 5/16

|

1 5/16

|

27/32

|

5.7

|

|

53V530SK

|

SK

|

A

|

5.25"

|

5.30"

|

5/32

|

2 5/16

|

1 15/16

|

7/32

|

6.5

|

|

53V560SK

|

SK

|

A

|

5.55"

|

5.60"

|

5/32

|

2 5/16

|

1 15/16

|

7/32

|

7.5

|

|

53V600SK

|

SK

|

A

|

5.95"

|

6.00"

|

5/32

|

2 5/16

|

1 15/16

|

7/32

|

8.9

|

|

53V650SK

|

SK

|

A

|

6.45"

|

6.50"

|

5/32

|

2 5/16

|

1 15/16

|

7/32

|

10.6

|

|

53V690SK

|

SK

|

A

|

6.85"

|

6.90"

|

5/32

|

2 5/16

|

1 15/16

|

7/32

|

12.8

|

|

53V800SK

|

SK

|

A

|

7.95"

|

8.00"

|

5/32

|

2 5/16

|

1 15/16

|

7/32

|

13.6

|

|

53V1060SK

|

SK

|

A

|

10.55"

|

10.60"

|

5/32

|

2 5/16

|

1 15/16

|

7/32

|

17.0

|

|

53V1400SF

|

SF

|

A

|

13.95"

|

14.00"

|

1/32

|

2 5/16

|

2 1/16

|

7/32

|

26.0

|

|

53V1900SF

|

SF

|

A

|

18.95"

|

19.00"

|

1/32

|

2 5/16

|

2 1/16

|

7/32

|

41.0

|

|

53V2500E

|

E

|

D

|

24.95"

|

25.00"

|

17/32

|

2 5/16

|

2 3/4

|

3/32

|

63.0

|

|

53V3350E

|

E

|

D

|

33.45"

|

33.50"

|

17/32

|

2 5/16

|

2 3/4

|

3/32

|

95.0

|

The daily inspection of pulley depends on these three aspects

The daily inspection of pulley depends on these three aspects

Address

Luotuo Industrial Area, Zhenhai District, Ningbo City, China

Tel