About Us

Raydafon Transmission is your ISO 9001-certified partner for precision gearboxes and reducers. Since 2011, we’ve engineered robust transmission systems for agriculture, mining, and hydraulics industries across 50+ countries. With a 5,000㎡ smart facility and 120+ technicians, we deliver custom spiral bevel gearboxes, worm reducers, and valve bodies that outperform industry standards by 30% lifespan. Trusted by global OEMs, our 90-day production cycle and <0.5% defect rate ensure your machinery thrives. Request a catalog to discover how our $10M annual output powers your success.

About Us

Raydafon Technology Group Co.,Limited Established in 2011 in Hangzhou’s Luqiao Economic Development Zone, Hengchuang Transmission has evolved into a global leader specializing in R&D, manufacturing, and technical training for high-performance transmission systems. With a 5,000㎡ state-of-the-art facility and a skilled workforce of 120 professionals, we deliver an annual output valued at $10 million (RMB 70-80 million), empowering industries worldwide with innovative, reliable solutions. 1990

1990

Was Established In

500

500

Factory Area

50

50

Qualification Certificate

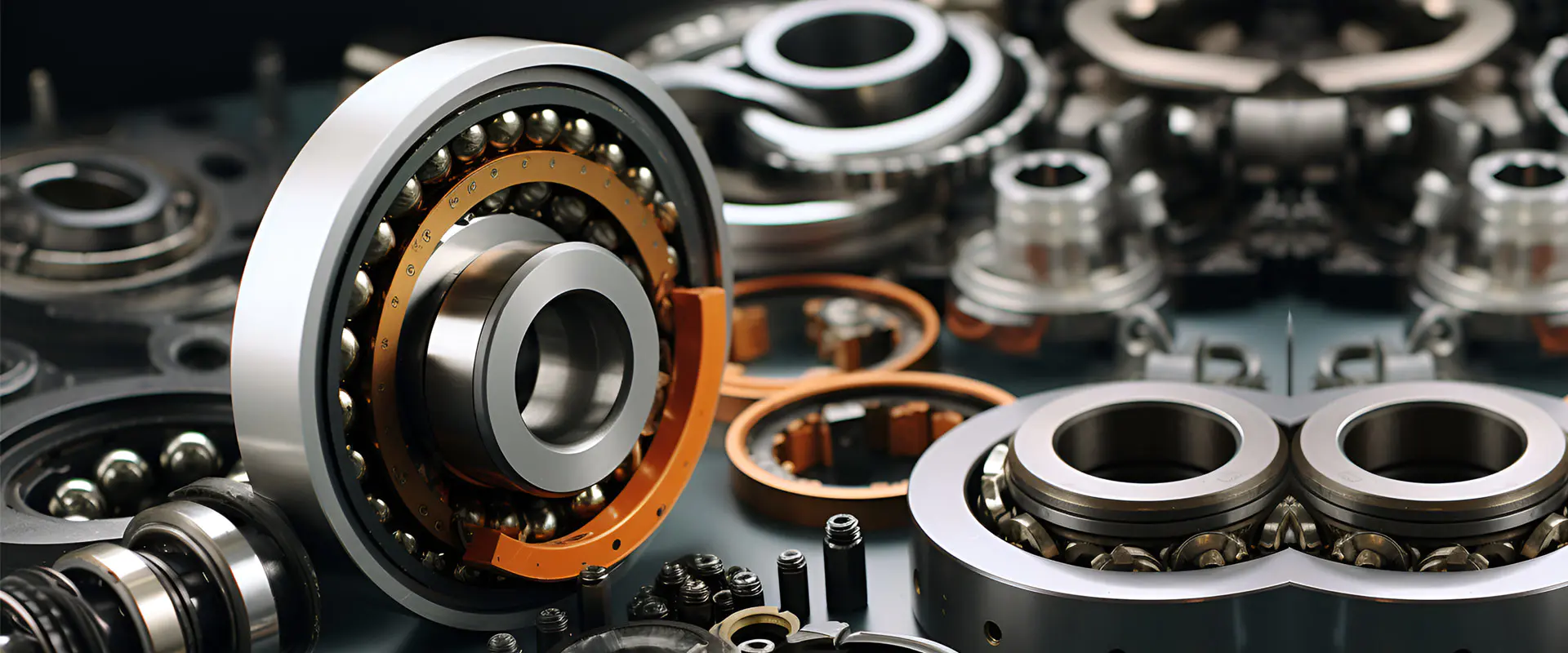

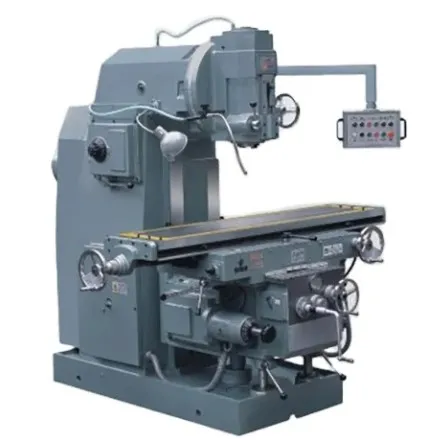

Featured Products

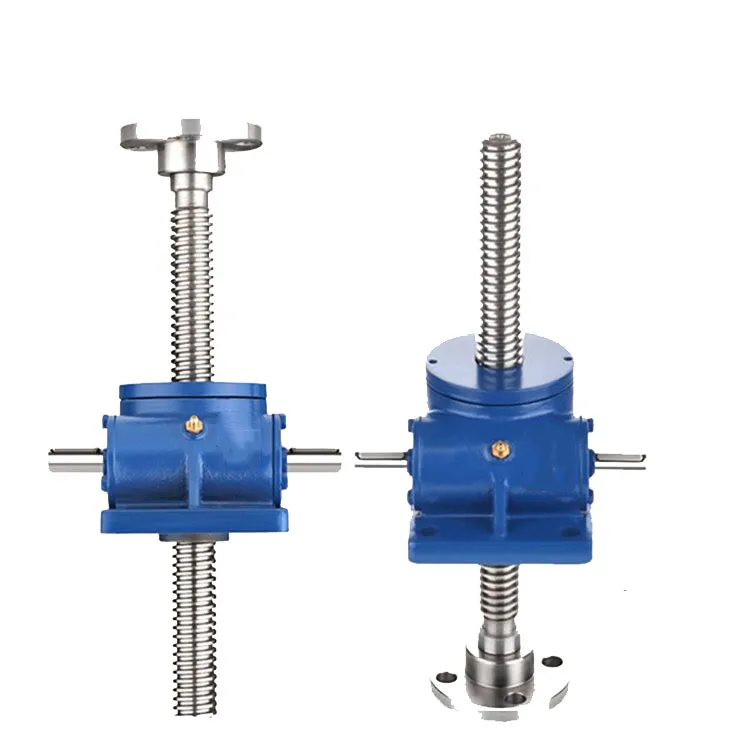

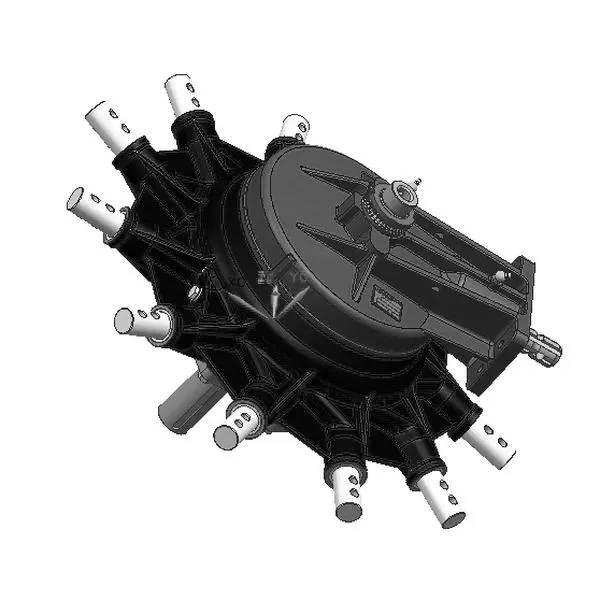

Latest ProductsExplore Hengchuang’s high-performance gear systems:

Spiral Bevel Gearboxes: Precision-engineered for heavy-duty tractors and mining conveyors.

Worm Reducers: Compact design for snow sweepers and grain elevators.

Hydraulic Valve Bodies: Withstand 400+ bar pressure in petroleum equipment.

All products undergo 18-stage quality checks, ensuring zero defects and compatibility with CAT, Kubota, and John Deere systems. Customize torque (10-10,000 Nm) and ratios (5:1 to 100:1) for your machinery.

Our Services

Preferential Prices

RAYFON is interested in nothing but the bowl of river water even though i stand in front of the river.

raed moreCase

Exploring mechanical transmission methods and their application examples

Worm gear mechanism, as one of the top ten mechanical transmission methods, is mainly used to transmit motion and power between two intersecting shafts. Its uniqueness lies in its smooth and noise free transmission characteristics.

Example of belt drive shaft breakage

For motors connected by pulleys, when some customers equip the motor output shaft with pulleys, if the pulleys are too heavy or the belt is installed too tightly, it can also cause the motor output shaft to experience continuous alternating bending stress during operation.